Metal | Concrete | Wood Cutting

1200W 184MM CIRCULAR SAW-DEDWE561

DEDWE561

The DeWalt DWE561 Compact Circular Saw is lightweight and easy to use with 65mm depth of cut.

Its high power 1,350 Watt motor gives increased cutting performance, and the cutaway inner guard gives improved line of sight to cutting line.

The DWE550 has a dust blower, which clears dust and debris from the cut line.

The efficient dust extraction port minimises airborne dust particles when connected to a dust extraction unit.

The circular saw has direct compatibility with DEWALT AirLock system for easy, secure connection to extraction hose.

₱16,813.00

190MM CIRCULAR SAW - SCS65Q

SCS65Q

What is a demolition hammer?

The demolition hammer is one of

the power tools specifically designed

for the demolition of the structure.

It is also known as stomping hammers.

Demolition hammer tools are strong

enough to break down various materials

such as wooden walls, concrete surfaces

and tile flooring.

Jackhammers, also known as

demolition hammers or concrete

breakers, are the primary tool

in the breaking of old or non-standard

structures and are a must-have

for construction and renovation

projects that often involve tearing

down concrete slabs, tiles, or brick walls.

A hammer drill, also known as a

percussion drill or impact drill,

is a power tool used chiefly for

drilling in hard materials. It is a

type of rotary drill with an impact

mechanism that generates a

hammering motion.

Hammers are powerful

enough to break up blocks of

brick and concrete with ease.

Our breaker hammers work with

many Cat machines, meaning you

can quickly transform your existing

equipment into a robust demolition

tool just by renting a breaker hammer.

It is perfect for demolition,

trenching, chipping,

breaking holes in concrete,

block, brick, tile stucco, housing

foundation removal, concrete slab

, oil chimney and much more!

SDS is short for Slotted Drive

Shaft or Slotted Drive System.

These drills are typically

used for heavy-duty drilling into

materials such as brick, stone,

oncrete and other types of masonry.

Unlike regular drills, they have a

SDS is short for Slotted Drive Shaft

or Slotted Drive System.

These drills are typically u

sed for heavy-duty drilling into

materials such as brick, stone,

concrete and other types of masonry.

Unlike regular drills, they have a unique

design that provides a high level of power

during drilling.

₱48,000.00

₱60,000.00

Argo CIRCULAR SAW 190MM/7.5 4700RPM, ARGMTCS1400

ARGMTCS1400

CIRCULAR SAW 190MM/7.5 4700RPM 1400W

₱4,399.00

Argo Electric Planer 1MM X 82MM, ARGMTEP600

ARGMTEP600

Electric Planer 1MM X 82MM 16000RPM 600W

₱3,999.00

CUT OFF MACHINE - ZEKOKI

ZKK-3550LS , ZKK-3550CS

CUT OFF MACHINE - ZEKOKI MODEL #

ZKK-3550CS - 355MM CUT OFF MACHINE

ZKK-3550LS - 355 MM CUT OFF MACHINE

From ₱10,001.00

Dewalt Circular Saw, Lightweight, Corded Advantage 1200W, 185mm Compact, DWE561-B1

DWE561-B1

Dewalt Circular Saw, Lightweight, Corded Advantage 1200W, 185mm Compact

₱13,450.00

DEWALT DCS391N-XJ XR 165 mm Circular Saw-Bare Unit, 9 W, 18 V, Yellow/Black -DEDCS391N

DEDCS391N

DEWALT DCS391N-XJ XR 165 mm Circular Saw-Bare Unit, 9 W, 18 V, Yellow/Black

₱23,650.00

Dewalt Jigsaw, Top handle Compact Jigsaw + Corded, Variable-Speed 550W, DW341K-B1

DW341K-B1

Dewalt Jigsaw, Top handle Compact Jigsaw + Corded, Variable-Speed 550W

₱14,945.00

Dewalt Laminate Trimmer , Cordless Router, Brushless, Tool Only, (200W, 25.4mm) , DWE6000-B1

DWE6000-B1

Dewalt Laminate Trimmer , Cordless Router, Brushless, Tool Only, (200W, 25.4mm)

₱15,200.00

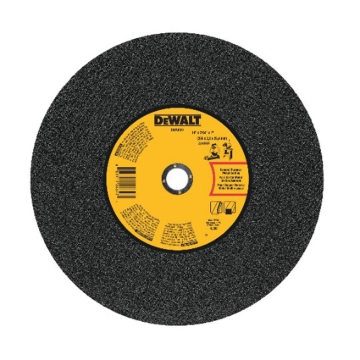

Dewalt Metal Cutting Disc, Cut off Wheel, Stainless Steel+ Aluminum Oxide, Ultra Thin Cutting Disc, 14" , DWA8011R

DWA8011R

Dewalt Metal Cutting Disc, Cut off Wheel, Stainless Steel+ Aluminum Oxide, Ultra Thin Cutting Disc, 14"

₱270.00

Dewalt Portable Hand Planer + Cable , 550W, 1.5mm, D26676-B1

D26676-B1

Dewalt Portable Hand Planer + Cable , 550W, 1.5mm

₱14,038.00

INGCO 12pcs 1/4inch Router Bits Set (6mm), AKRT12141

AKRT12141

INGCO 12pcs 1/4inch Router Bits Set (6mm) AKRT12141

₱950.00

Min:

₱0.00

Max:

₱123,950.00

₱0

₱123950